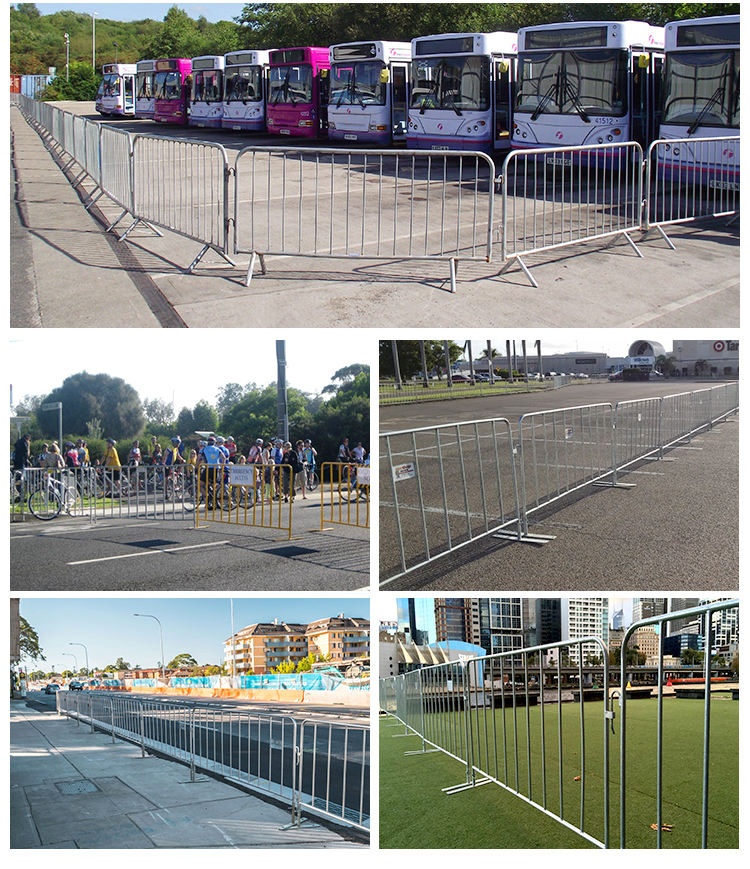

Crowd control safety barriers are an essential tool for controlling large crowds and maintaining order in public spaces. These barriers are designed to discourage transgression and physically encourage directional order and crowd control. Here are some key details about crowd control safety barriers:

Our crowd control safety barriers are made with pre-galvanized steel tubing, with a 38mm diameter and 1.8mm thickness. The outer frame is a single length of tubing without welds or deformation, bent at right angles with a minimum of smooth deformation. The horizontal and vertical bars are at right angles to the overall frame. Our barriers are available in a variety of sizes and spacing, with detached flat feet, bridge feet, or settled v-type feet. They can be hot-dipped galvanized, PVC, or galvanized.

Video Of Powder Coated Crowd Control Safety Barriers

specifications for our crowd control safety barriers:

| Specification | Detail |

|---|---|

| Panel Size | 1.1m x 2.1m, 1.1m x 2.2m, 1.1m x 2.5m, 1.2m x 2.5m |

| Spacing | 100mm, 120mm, 150mm, 190mm, 200mm |

| Feet | Detached flat feet, bridge feet, settled v-type feet |

| Frame and Middle Pipe | 25mm, 32mm, 38mm, 42mm, 48mm or as per customer's requirement |

| Surface Treatment | Hot dipped galvanized, PVC, galvanized |

| Feature | Solid and robust, easy to handle and remove, weather-resistant |

| Customization | Panel shape or specification can be customized |

Our crowd control safety barriers are available in a variety of sizes and spacing, with detached flat feet, bridge feet, or settled v-type feet. They can be hot-dipped galvanized, PVC, or galvanized. We also offer customization options for panel shape or specification to meet the unique needs of our customers.

Applications:

Crowd control safety barriers are commonly used at public events, concerts, and festivals to guide pedestrian traffic, prevent unauthorized access, and keep the public safe. They are also used by law enforcement agencies to control large gatherings, create barriers for parades or demonstrations, and protect sensitive areas.

The production process of crowd control barriers involves several steps to ensure a durable and high-quality product. Here are the steps involved in the production process of crowd control barriers:

-

Material Selection: The first step is the selection of high-quality materials such as pre-galvanized steel tubing. The outer frame is a single length of tubing without welds or deformation. The pipe is bent at right angles with minimal smooth deformation. Horizontal and vertical bars are at right angles to the overall frame.

-

Cutting and Bending: The selected materials are then cut and bent according to the required dimensions using specialized equipment.

-

Welding: The cut and bent components are then welded together to form the frame of the crowd control barrier. The welding process ensures that the barrier is strong and durable.

-

Surface Treatment: After welding, the barrier undergoes surface treatment such as hot-dipped galvanization or powder coating. This process protects the barrier from rust and corrosion, making it more durable and weather-resistant.

-

Assembly: The components of the crowd control barrier, including the frame and feet, are assembled together. Detachable feet are available to make the barriers easy to transport and store.

-

Quality Control: Before being packaged and shipped, each barrier undergoes a quality control inspection to ensure that it meets the required standards and specifications.

-

Packaging and Shipping: The final step involves packaging the crowd control barriers in a way that ensures they arrive at their destination in excellent condition. Plastic film, metal corners, and wooden pallets are used to protect the barriers during transportation.

Packing and Delivery crowd control safety barriers :

At our crowd control safety barriers factory, we take great care to ensure that our products are packaged and delivered in excellent condition. Our barriers are wrapped in plastic film to protect them during transportation, and we use four metal corners to ensure the panel is strong and uniform. A wood plate is placed at the top of the pallet to keep the under panel safe, and the pallet tube size is 40*80mm tubes at the bottom vertical position. We work with reliable shipping companies to ensure that our products are delivered safely and on time.

In conclusion, crowd control safety barriers are an essential tool for managing large crowds and maintaining order in public spaces. Our crowd control safety barriers are designed to be robust, weather-resistant, and easy to handle, making them an excellent choice for any event or situation where crowd control is essential.

Boss Metal And Plastic Co Limited

Boss Metal And Plastic Co Limited